About SGI

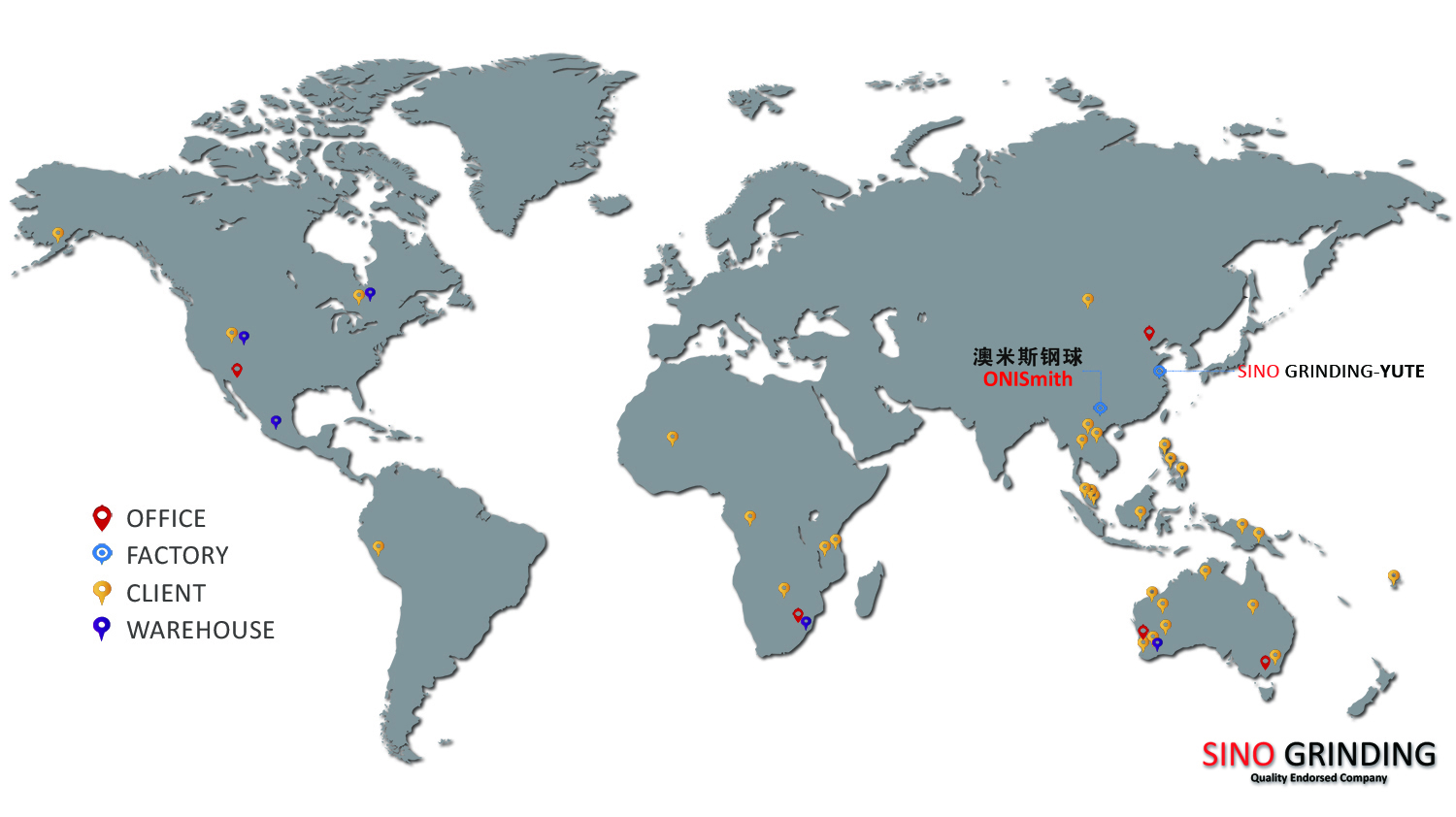

Global Supply Solutions

Sino Grinding International (SGI) is a global company specializing in the design, manufacturing and distribution of grinding media. Our regional marketing offices offer regular on-site technical and logistical support. Our customers benefit from SGI’s proactive product development and site-specific adjustments to meet their milling requirements, and gain the advantage of a supplier who wants to work side-by-side to improve grinding circuit performance. Our metallurgical expertise and grinding media designs are second to none.

Each processing site is unique and requires a custom solution. All of our ball grades are adjustable to meet milling targets. In many cases SGI will work out a transitional strategy with the client to purge existing media and replace it with one of SGI’s premium grades.

Manufacturing & Production Capacity

Sino Grinding has meticulously built and trained two manufacturing facilities with large production capacity in China to make our grinding balls. The facilities are located in Southern China and South-Western China in order to take advantage of local resources and ensure security of supply to our clients. The total ball manufacturing capacity of these facilities is over 200,000mt per annum.

Employees: 100+

Capacity: 100,000 metric tonnes of roll-forged balls & 50,000 metric tonnes of hammer-forged balls per annum

Products: SAG & BALL mill balls

Product Diameter Range: 20 to 160 mm

Employees: 60+

Capacity: 20,000 metric tonnes of roll-forged balls & 30,000 metric tonnes of hammer-forged balls per annum

Products: SAG & BALL mill balls

Product Diameter Range: 30 to 125 mm

SGI performs technical research and laboratory testing for future developments at both of these manufacturing facilities.

World Class Products

SGI leads the market with technical design and quality control of SAG and ball mill grinding media production. Our approach is to work with customers to improve performance by:

- Decreasing steel consumption,

- Decreasing cost per tonne of ore milled,

- Improving grind (particle distribution), and

- Increasing throughput.

Safety is our first priority

SGI is recognized under ISO 9001 quality management certification. Safety is SGI’s primary concern throughout all our processes:

- manufacturing,

- logistics, and

- office & on-site personnel.

SGI remains very active in the improvement of working conditions for our employees, partners and customers.

Take a look at the Safety Data Sheet (SDS) we developed for our customers’ use.

Our Global Presence

Contact SGI today for enquiries regarding our products.